There is a need to bring the focus back on circularity and the world is taking notice. Politicians, academicians, corporate honchos, and numerous bodies such as the World Economic Forum and OECD have called for a transition to circular economy.

Linear vs Circular

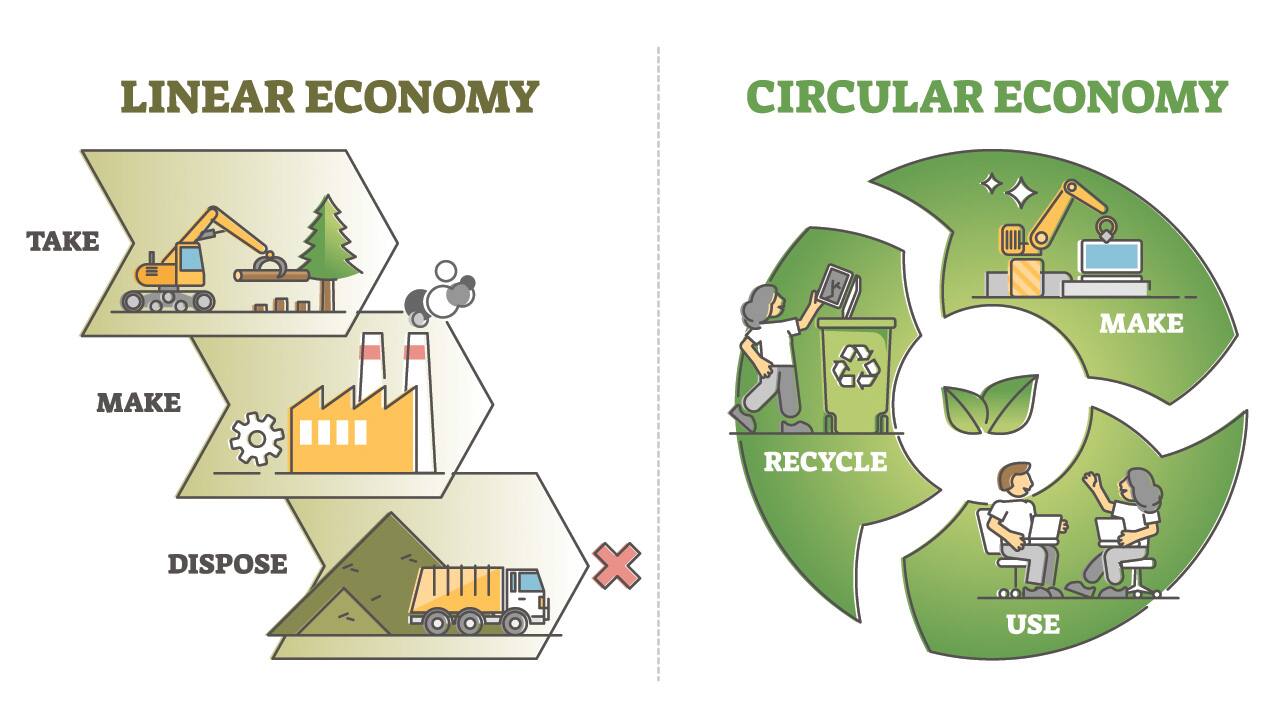

The difference between linear and circular models is very pronounced. Circular economy is an economic system which is designed to preserve raw materials and eliminate waste throughout the value chain; be it production or manufacturing. Circular economy emphasises on a sustainable approach to processes and material. It is much more flexible and adaptable as per the real-world scenario. By incorporating real-world issues, companies are not only able to address issues of environment and development, but also ensure longevity. In that manner, a circular model serves as a two-way mechanism where corporate actions that benefit the world can also help the company.

Little wonder then that companies across the world are evaluating the circular model and adopting them within their systems in different ways. Take for instance, sportswear manufacturer Adidas is now successfully converting plastic waste collected from the ocean into raw material for its shoes. Meanwhile, on the other end, denim major Levi Strauss & Co. is not only investing resources into finding new ways to create clothes with lesser environmental impact, but also sharing them with the world at large, even with its competition. A circular model is a collaborative approach that is holistic and encompasses all functions of the company.

Charting the shift

The shift from a linear model to that of a circular one is necessary, but is not an easy one to make. It needs a complete realignment of the business ethos, with ingraining sustainability into every aspect, from manufacturing to delivery and how to deal with customers.

According to the Ellen MacArthur Foundation, here are some of the key principles that a company can follow:

To aid the adoption of a circular economy, the United Nations General Assembly crafted the Sustainable Development Goals (SDGs), a collection of 17 interlinked global goals that serve as a blueprint to achieving a more sustainable future for all by 2030. Companies can commit themselves to several of these goals and try to incorporate them into the functions.

There are different business models that are crafted around the concept of circularity, and they vary from business to business. For instance, OECD has crafted five such models. Broadly, they can be coalesced into three categories, namely,

To understand these three categories, let's look at what AB InBev, the world's leading brewer of brands like Budweiser, Corona, and Hoegaarden, is undertaking to improve its circularity. To start with, the company launched its 2025 sustainable goals, in line with the UN SDGs, that incorporate various aspects of sustainability into the business. Here's how AB InBev has incorporated circularity in its various aspects.

Circular Sourcing

Ethical and sustainable sourcing of raw material is one of the most important aspects of circularity. By ensuring raw materials are grown in a sustainable manner, companies can significantly achieve their ambition of going green. SDG #12 (ensure sustainable consumption and production patterns) maps to circular sourcing. AB InBev has put in place a whole range of steps to ensure that the products sourced are of the highest quality, and that the producers are adequately compensated. In India, the company works with 1200+ farmers to procure the best quality barley crop and help them up-skill through technology interventions.

Circular Manufacturing

A critical aspect of circular manufacturing is to reduce waste, while also minimising its environmental footprint. Availability of potable water is critical in this regard, and so is the usage of sustainable and renewable electricity. Here, AB InBev has implemented ways to improve water efficiency, by reducing the amount needed to make a litre of beer by as much as 40%. In the area of renewable electricity, the company is actively sourcing its power through renewable sources, and has already achieved ~73% adoption at one of its breweries in India.

In addition, AB InBev is continually exploring new business ideas to incorporate circularity. For instance, it recently launched a protein drink in some markets which is made from spent grains, a by-product of the brewing process—which previously were only resold as animal feed.

Circular Distribution

Packaging is one of the core aspects of circularity. With tonnes of plastic finding its way to oceans and landfills every year, cutting down on plastic waste has become a pertinent issue with all companies. AB InBev is also actively working towards making its packaging sustainable. It is cutting down on packaging materials. Its glass bottles in India contain 35% recycled content while the cans are made up of approximately 76% of recycled material. Its 2025 goal is to ensure 100% of its product to be in packaging that is returnable or made from majority-recycled content.

In all, the circular economy model is not an option anymore, it has become a necessity when you consider the realities of our take-make-waste system: rising CO2 levels, increase in population, depleting resources, just to name a few. The circular system, be it in terms of manufacturing, packaging, or distribution, needs to be ingrained in everything that companies do. The shift from the linear model to a closed loop one has already started and companies like AB InBev are setting benchmarks for the rest of the industry to follow.Se